“Yes is does!” exclaims Farrell Allison, Crop Quest Agronomist in the Dodge City, KS Division. “At times, Precision Agriculture information and technology can be overwhelming but once all the pieces are together, it does pay,” he states.

Allison consults on approximately 40 fields that are using some type of Precision Agriculture (PA) system. The most common forms of PA services his producers use are zone sampling and variable rate fertilizer recommendations. Determining soil type from electrical conductivity (EC) data collected using Veris technology is the major reason his producers began using PA services. RTK field elevation is another reason many producers decided to get their feet wet in PA.

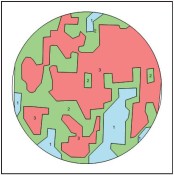

By overlaying various maps generated from PA information, Allison and his clients were able to reach yield potentials in the respective zones. “By matching yield to soil type and/or elevation, it helps to determine the potential productivity of the field and establish zones for populations & fertility. It was amazing and exciting to see those potentials being reached,” states Allison. “We can really see what’s going on and the progress being made in each zone.”

Examples of the benefits of PA information from Allison’s producers are:

- Grid samples can show where fertilizer (manure) didn’t spread evenly.

- Lime applications – lime is expensive. If only ¼ to ? of a field needs lime, the reduction in total lime applied would result in tremendous savings (Allison has seen savings as much as $75 per acre).

- In sandy soil, one particular dryland corner had been yielding 15 bushels an acre. With the implementation of PA services, the yield increased to 25 bushels per acre from using a variable rate lime application.

- Last year, a producer had a 550 gpm well. This year, the same producer ended up with about 450 gpm. Because the field was short on water, they cut the population in lower producing areas (which were very sandy soils). Overall yields were much better than expected. In very dry years, his customers are seeing improvement in yields, profitability and water usage by implementing PA services.

“The producers in my area that use variable rate applications have saved money overall on fertilizer, pesticides and seed costs,” states Craig Koehn, Crop Quest Agronomist in the Montezuma, KS division. Producers in his area are interested in knowing fertility levels, identifying yield variability and targeting problem areas. Koehn starts all PA programs based upon EC data from Veris technology. The EC data and yield data are then used to create variable rate maps and recommendations. Utilizing the total PA package makes the farming operation more efficient. “In addition to yield maps and variable rate recommendations, equipment manufacturers have technology such as swath width control and boom control to prevent overlap when the machine reaches the edge of a field. Today’s farming practices are much more precise and efficient,” Koehn emphasizes.

On the other hand, input costs are not always reduced with the implementation of Precision Ag. “I have done the math on fertilizer expense with and without utilizing variable rate applications, and my producers actually spend more money per circle using variable rate application – as more is typically spent on phosphorus, slightly more on nitrogen, but seeing some savings on zinc and potassium,” explains Sam Turner, Crop Quest Agronomist in the Ulysses, KS division. Precision Ag programs provide for better stewardship of the land by placing the nutrients where they are needed most. “PA makes the operation more efficient and will increase overall yields which in turn will have a positive impact on a producer’s bottom line,” adds Turner.

“Variable rate application is profitable, but it is not as effective in cutting costs as others may advise,” concludes Turner. An overall PA system will benefit a producer. PA data provides more accurate information for better decision making & recommendations. Variable rate applications may not always be cheaper, but PA should enhance the bottom line with the increase in efficiency and yield.

Precision Agriculture perfects the fertilizer program to avoid over or under fertilizing. It also aids in variable rate planting in the same manner. PA technology can help stabilize fertility in different areas of the field, and over time there may be increased yields in the better producing areas with less focus on low producing areas. “A Precision Ag system is going to fine-tune the over-all operation, and the producer must trust the knowledge & relationship with their agronomist providing the recommendations,” stresses Allison. “Producers need to look at long term and future planning – Precision Agriculture is about looking down the road. The more information a producer has, the more valuable the land will be,” he concludes. For further information and examples please visit the Precision Ag page on the Crop Quest website at www.cropquest.com/precision-ag.