EC & EM SOIL TEXTURE MAPPING

Long Term Thinking Yields Dividends

It all starts with the soil. It takes about 300 years to form 3/8 inch of soil in a mild climate. The soils we farm were formed over thousands of years, and if managed well that same soil will be around for generations to come.

Soil texture does not change; which is why Veris EC or Geonics EM38 soil mapping are typically one time operations. Good or bad we can expect to farm the same soil texture as long as we remain stewards of that land.

“It makes sense to understand a resource that is relied on for a lifetime.”

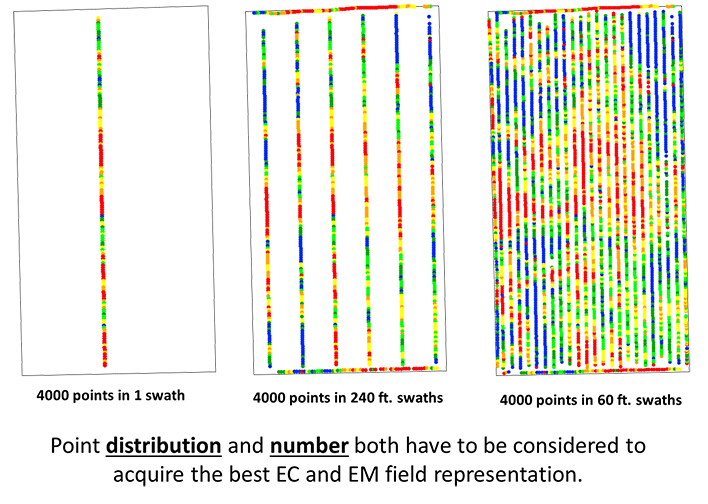

Both Veris EC mapping and EM38 soil mapping leverage the soils ability to conduct electricity. The soils conductivity is related to the particle size, soil moisture, and salt content. By measuring and mapping the differences in the soil ec we can differentiate between soil textures, e.g. clay’s conductivity is higher than sands. Properly calibrated, these soil sensors are also capable of mapping variations in soil salinity.

The soil affects everything, from seed to fertilizer to herbicides. A one time investment in soil texture mapping gives a better understanding of the crops underlying resource. This information has the potential to yield dividends year in and year out because the layer has no expiration date.

![]()

Setting the Pace

New technologies are being introduced every day. A trend that will likely continue to pick up speed as we find more uses for layers like EC, and acquire layers such as crop health imagery.

EC & EM soil mapping both provide a consistent layer which can be used to create management zones for variable rate seeding, fertilizing, and irrigation. We have experience with these soil sensors and the expertise needed to incorporate them into your farming operation.

Maximizing Input Efficiency with Soil Mapping

Combining EC & EM soil mapping with producer / crop consultant knowledge and options are revealed for variable rate application of seed, fertilizer, and water. By optimizing the placement of inputs, the potential for a return on investment improves. The opposite can also be said. By not placing inputs in areas with poor soil, dollars can be saved or shifted to other locations. In short, good input placement leads to higher farm profits.

Your Soil, Your Data, Your Choice

Simply put, the data collected is the clients. The variable rate prescriptions generated go where you decide to send them. In other words, as an independent crop consulting company we make every effort to advance the farmers objectives.